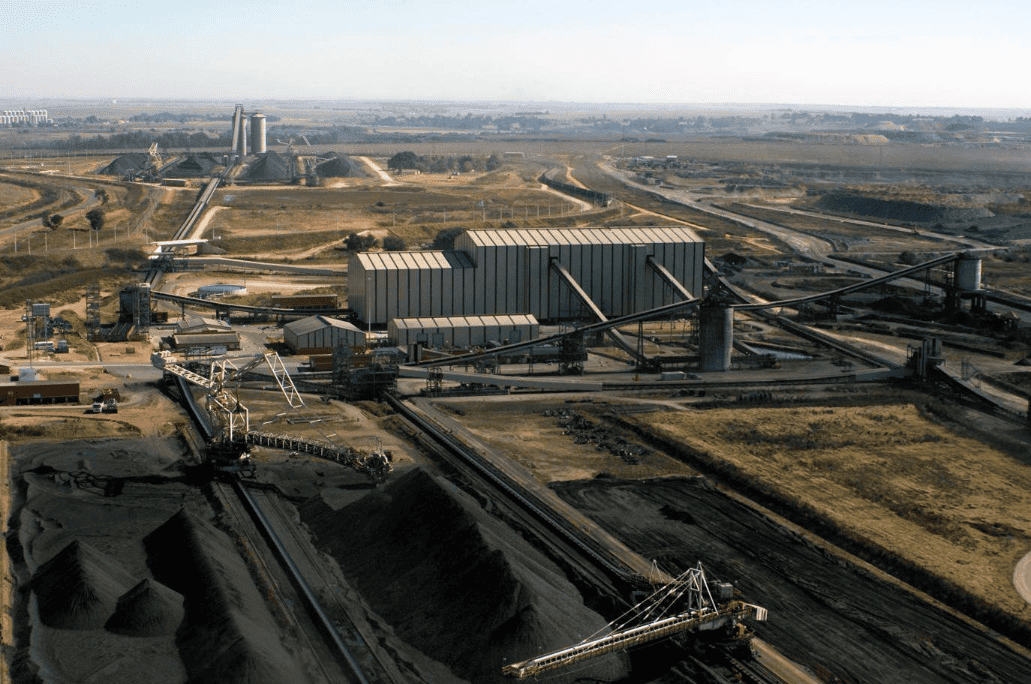

| Client: | BHP Billiton and Anglo Coal |

| Location: | South Africa |

| Value: | USD$ 100 million |

| Scope: | Engineering, Procurement and Construction Management |

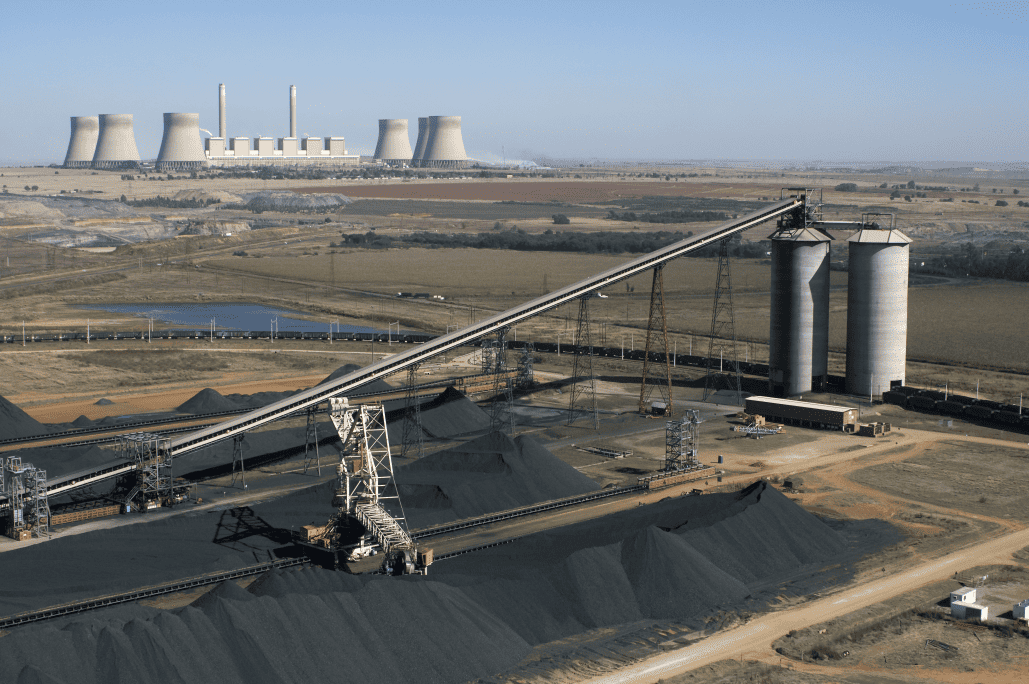

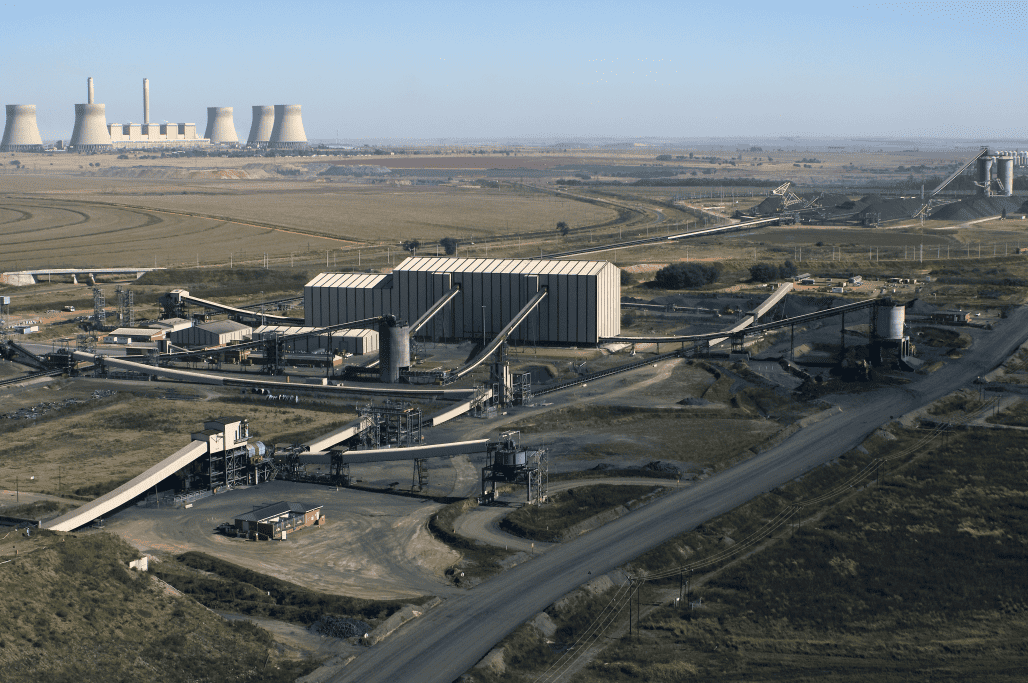

Phola Coal, a 50/50 joint venture between, Anglo American Coal (AAC) and BHP Billiton Energy Coal South Africa (BECSA) called for the design and construction of a 16 Mtpa coal processing plant. DRA Global was awarded the US$100 million Phola Coal project, the largest coal washing facility in South Africa. This followed a successful study of the engineering design, procurement, project management, construction management and commissioning of the project. Minopex supported the commissioning of the Phola project and has operated and maintained this facility since it was completed in 2010.

At that time, the two module 2 360 t/h plant incorporated possibly the largest modular throughput capacity sections in the world at 1 180 t/h each. DRA Global achieved this by splitting the 50 x 0,63 mm raw coal dense-media separator (DMS) section feed into coarse and small coal fractions, which were processed in parallel through separate low-density sections to make a 27,5 MJ/kg export product.

The plant also used standard DMS technology incorporating the largest size of screens and dense medium cyclones, then available in South Africa. All the process equipment was locally manufactured.

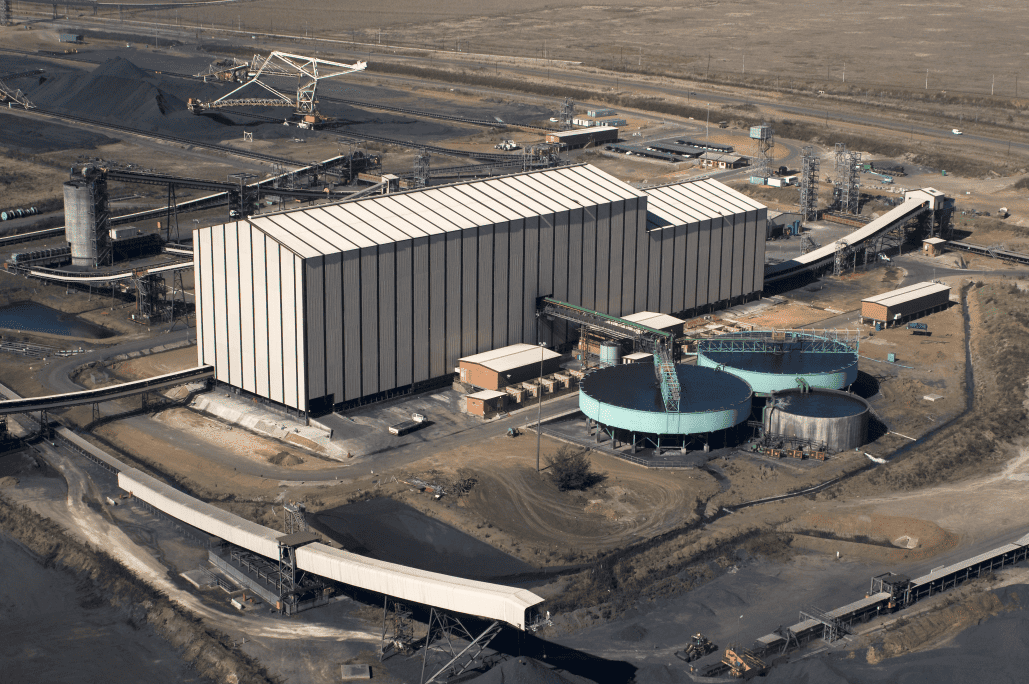

The Phola coal beneficiation plant is situated in an environmentally sensitive area, the presence of a slimes dam was prohibited. This meant that slimes had to be filtered, but with the benefit that they can be added directly to the Eskom product if the filter cake quality was sufficient. This resulted in the installation of one of the largest filter press plants in the coal preparation world, designed to treat up to 190 t/h of raw coal slimes.