| Client: | Kamoa Copper (JV Between Ivanhoe Mines and Zijin Mining) |

| Location: | Democratic Republic of Congo (DRC) |

| Contract Value: | EPCM Manhours Budget – 52 Million USD/ Capex under DRA Control – 675 Million USD |

| Project Value: | 1.3 Billion USD |

| Period: | January 2019 - June 2021 |

| Scope: | Engineering, Procurement & Construction Management |

| Throughput: | 3.8 Mtpa | Copper |

The greater Kamao Kakula Complex boasts 5 distinct orebodies, that Kamoa is planning to access via multiple decline systems located in three dedicated mining areas. Furthermore the complex will have 5 off 3.8 MTPA concentrator plants and a smelter, taking the planned production to a peak of 19 MTPA.

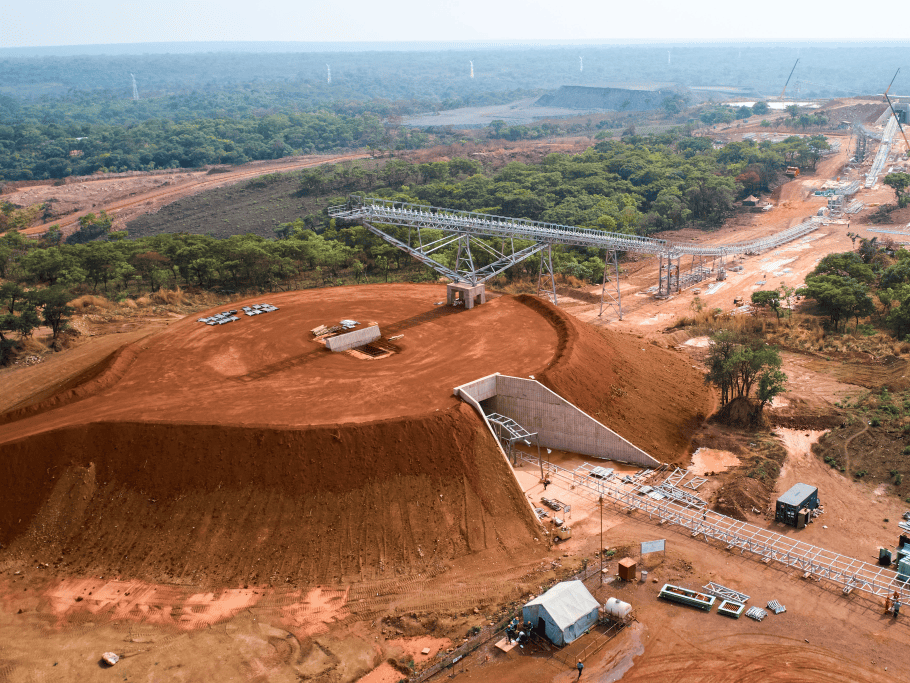

The Kamao orebody has been independently ranked as one of the richest copper ore bodies in the world. Kakula’s expected average ore-feed grade is 6.6% copper, and mine-site cash cost of US$0.48/lb copper, in the first five years of operation. To date 671,000 tons grading 3.36% copper, including 116,000 tons of high-grade ore grading 6.08% copper, has been mined and stockpiled for process plant startup.

DRA has been involved with Kamoa on the Kamoa project from 2017, conducted multiple studies and commenced with the execution phase of the project in January 2019, with planned commissioning being Q2 in 2021

Scope of Work

DRA’s scope of work is full EPCM services associated with Mining and Mining Infrastructure, Concentrator Process Plant and the projects Bulk Support Infrastructure.

The mining scope comprise multiple underground tips and conveyor systems, which include - a first for Africa - 2000tph decline conveyor belt. Further included are multiple dewatering pumping systems, at a total capacity of 1,000+ liters/second.

The UG fleet procured by DRA includes the largest LHD’s and Dump Trucks available being 21 Ton LHD’s and 63 Ton dump trucks.

Other than typical mine surface infrastructure, the scope includes for the worlds largest paste backfill plant.

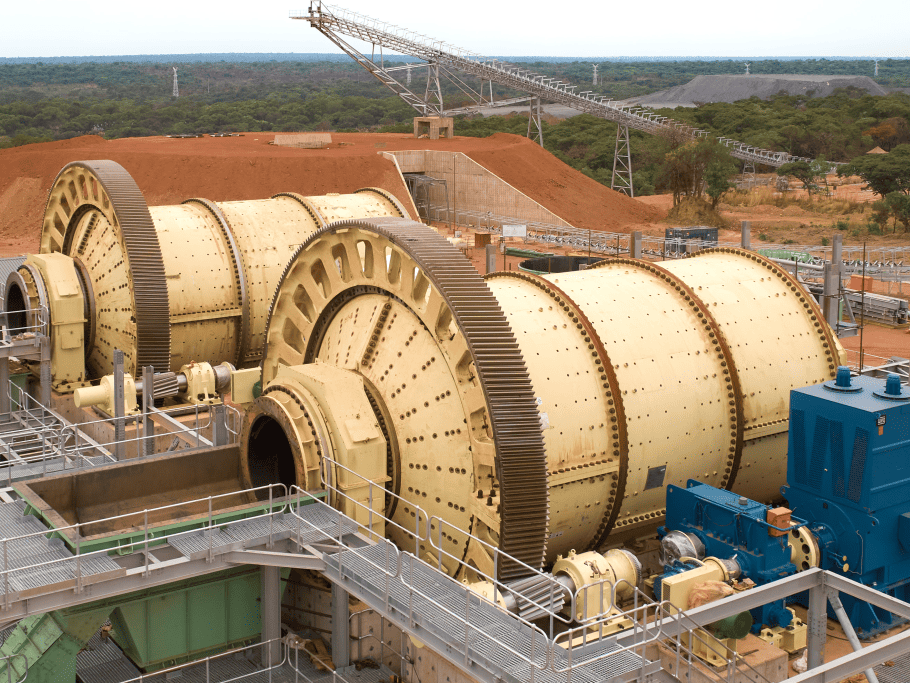

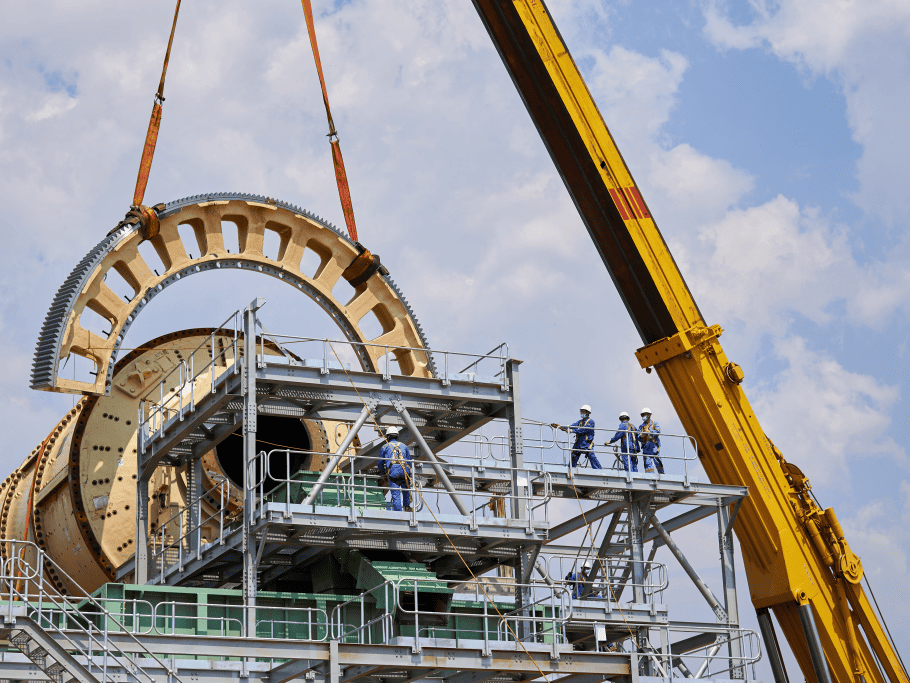

The process plant scope include for a single stream 3.8MTPA Concentrator plant, comprising an HPGR in circuit with Two stage ball milling, 300M3 rougher flotation cells, cleaner circuit including the use of Jameson Cells, typical tailings and concentrate handling circuits and filter press with a bagging plant, effectively producing four truckloads of concentrate per hour. ,

The general infrastructure include approx. 50 km of national roads network between Kolwezi and the mine, as well as multiple km’s of internal roads. It further includes the bulk power supply comprising 40Km’s of 220KV overhead line, upgrades to an existing 400MVA substation and the mine site 160MVA, 220KV/33KV Substation. As part of the scope the accommodation encompass the Kakula Village, which is a fully functional township to initially cater for 1600 people. Bulk water supply and water handling from UG and stormwater also comprise a notable portion of the scope. The tailings dam , located 7 km from the plant, complete with tailings lines to and water lines from the facility is included as part of the general infrastructure.

Key Accomplishments

Unique Features

Key Quantities

| Client: | Kamoa Copper SA |

| Location: | Democratic Republic of Congo (DRC) |

| Value: | US$1 billion |

| Period: | 2017- 2018 |

| Scope: | 6 Mtpa Pre Feasibility Study for the Greenfields UG copper mine |

The Kamoa-Kakula deposit is the world’s largest high grade, copper-only deposit, located in the Democratic Republic of Congo. Kamoa Copper SA was a joint venture between Ivanhoe Mines, Zijin Mining Group Co, Ltd. and the Government of the Democratic Republic of Congo. The Kakula deposit was independently ranked as the world's largest, undeveloped, high yield, high-grade copper discovery and the Kakula resource was estimated at 174 million tons at a grade of 5.62% copper.

Kamoa Copper SA conducted a PFS, on their Kakula East mine, associated with the greater Kamoa-Kakula project. Indications from the Preliminary Economic Assessments (PEA) showed a feasible mine capacity of a predicted 6Mtpa copper production.

Services provided by DRA

The scope of services included PFS study work entailing mining, a process plant, associated bulk infrastructure and overall study management services.

From receipt of the mine design from Stantec, a six-month period remained to complete the study. The study schedule was set up to follow two critical paths, the first required:

The second critical path:

DRA Global provided Kamoa Copper SA with a complete and integrated solution for the mine, process and infrastructure scopes ensuring full value chain alignment, seamless design continuity and the financial benefit of shared project services. The engineering and design was developed to support early execution works and to conduct the PFS in parallel.