|

Client: |

Newmont Boddington Gold |

|

Location: |

Boddington, Western Australia |

|

Scope: |

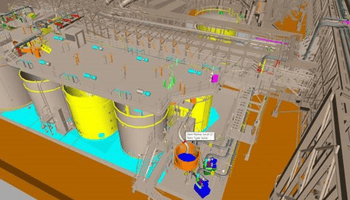

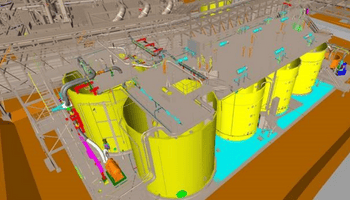

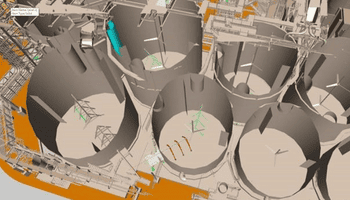

Staged Oxygen Addition, Reduce Gold Losses by Increasing Dissolved Oxygen Level in Gold Leaching Circuits, transfer chutes upgrade |

|

Period: |

2017 - 2020 |

DRA was engaged to undertake the engineering for Newmont Boddington Gold’s (NBG) Staged Oxygen Addition Project, Boddington WA. The primary objectives of the project were to increase oxygen addition to the CST Leach and CIL circuits. To do this DRA Pacific collaborated with NBG and formed an integrated team to undertake this brownfields upgrade. The project execution involved capex preparation, detailed engineering design, scope of works definition and technical support.

The project included the following components:

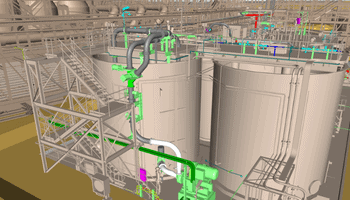

2019 DRA was engaged to reduce the final tail gold losses in solids by 0.01 g/t, through:

After the successful completion of the first two projects DRA was engaged for Transfer Chutes Upgrades.

The scope of work for the upgrade of the two HPGR Transfer Chutes consisted of the following items: